GM-IO Series Insulation Ink

- Commodity name: GM-IO Series Insulation Ink

Classification:

Keywords: Squeegee | Screen | Ink

Product Description

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

Product Characteristics

Printed products have excellent flexibility, the ink has excellent flexibility, suitable for die-cutting, convex, moulding and other processes.

Instructions for use

Normal use add diluent, stirring can be directly on the printing machine.

Diluent

Normal printing does not need to add thinner need to add

Please add specialized diluent

Thinner: C-8

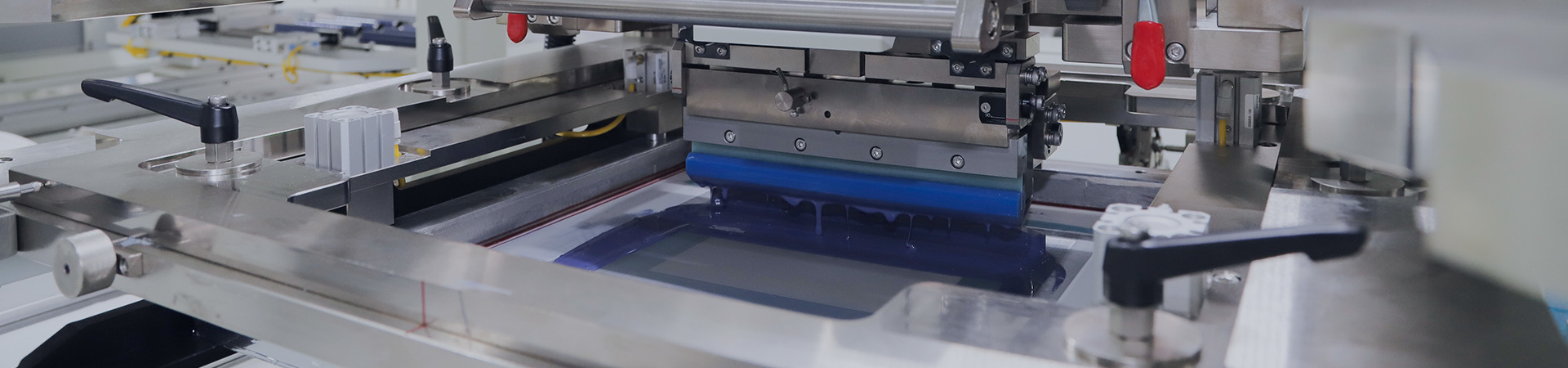

Screen and squeegee

We recommend a polyester or wire mesh screen with a mesh size of 300 mesh and a film thickness of 8 μm and a tension of 20 N for the photopolymer.

The best matching squeegee is 75A with a printing angle of 75°.

Printing materials

PC、ET、PVC

Curing conditions

One 120W/cm (300w/inch) or two 80W/cm (200w/inch) UV lamps.

Basic Physical Property Test

Colour:GM-IO-21306

Substrate:PET

Screen:300 mesh polyester mesh, 8 μ thick photopolymer film, 20 N tension

Drying: UV curing

Squeegee:SPS-9*50-300-75 °

| Test Items | Test Method | Result |

| Adhesion | BAG test 3M600 tape peeling | No peeling |

| Resistance value | 1,000 Mega ohms @ 1000VDC/25.4um | OK |

Storage

Insulation inks should be stored in a sealed environment at 15°-25°C. Shelf life is 1 year.

Disclaimer

The above data is obtained from laboratory tests and does not represent a guarantee of the quality of the end customer's use.

Despite the same parameters, there may be contradictory situations, only the purchase value and the value of use is guaranteed. Do not assume any responsibility and liability for any user, buyer, distributor and other individuals or enterprises due to direct or indirect, special or accidental reasons for loss, please test well to meet the requirements of the batch to continue to use!

Recommend products

SPS-AS carbon fiber squeegee for duplex drum screen printing machine

SPS-AS carbon fiber squeegee is suitable for reciprocating cylinder screen printing machine. It uses carbon fiber board and Japanese ASM anti-static solvent-resistant polyurethane rubber. The printing quality is stable and the service life is high.

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

In the process of screen printing, squeegee, screen plate, substrate material and other mutual friction, generating static electricity. When static electricity accumulates to a higher voltage difference, the edge of the pattern will produce flying ink, drawing and other bad.SPS-ASM anti-static squeegee resistance <108Ω, part of the charge through the squeegee dissipation, reduce the voltage difference, to avoid flying ink and wire drawing and other problems.

In the process of cell production, the effect of screen printing will directly affect the conversion efficiency of the cell, the core of printing is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must remain innovative, when writing higher screen printing requirements in just ten years, the requirements of the gate line is becoming more and more fine, has been from the initial 60um into the current 30um, or even finer; Subsequent to the replacement of the squeegee (as shown in the figure below), and now SPS-AS-SL single-sided photovoltaic carbon fibre squeegee is becoming more and more popular!

FGB-MP Glass Fibre Board Squeegee

SPS-MP-X series squeegee is a new generation of one-piece squeegee specially developed by Plet and Japan Polyurethane Chemical Company for the narrow line width printing of battery cells. Compared with the traditional sanding squeegee, it has significant effect on wet weight control, printing life and efficiency improvement, etc. Using this squeegee can achieve the purpose of cost reduction and efficiency improvement.

1. Manufactured using Japanese squeegee processing, it exhibits superior solvent and wear resistance; 2. The fiberglass board scraping glue combines the fiberglass board with scraping glue, offering the elasticity of the scraping glue and the structural support of the fiberglass board. This allows for a stable printing angle to be maintained even during extended periods, ensuring uniform ink thickness.