NPR-3800 Insulation Ink

- Commodity name: NPR-3800 Insulation Ink

- 柔性线路-COF: 1.Ink with excellent insulating properties</br> 2.2-liquid Ink with mixing of main agent and hardener</br> 3.Heat curing Ink

Introduction

Ink with excellent insulating properties

2-liquid Ink with mixing of main agent and hardener

Heat curing Ink

Shelf life

| Main polymers | Main polymer Useful life (days) | Hardener | Main polymer Useful life (days) |

| NPR-3800 | 180 | HARDENER NPR-3800 | 180 |

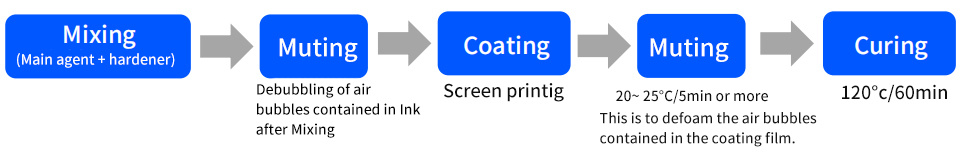

Standard process

Mixing process

●About mixing conditions

Type: Planetary centrifugal mixer ARE-310 (made by THINKY) Mixing conditions

Vessel capacity: 150ml, ink weight: 20-100g

●First step

Mixing mode

RPM/Rotation = 2000 / 800 rpm (2 min.); RPM Revolution>Rotation

●Second step

Defoaming mode

Number of revolutions / speed = 2000 / 54.5 rpm (2 minutes)

Revolution > Rotation and the ratio of rotation needs to be reduced compared to the mixing mode.

When mixing with a planetary centrifugal mixer, heat is generated by the shear heat, and the higher the mixing, the higher the Ink temperature.

A temperature of 35-45°C is ideal for mixing.

After mixing, it is necessary to let the Ink stand until it returns to room temperature (4 hours or more).

During this period, the air bubbles inside Ink will float up to reduce the air bubbles.

Sufficient defoaming time is required after screen printing and heat curing must be done only after defoaming is complete.

Also, if the printing environment temperature is too high, this will cause the solvent to evaporate faster, resulting in air bubbles remaining on the coating film.

Precautions for Screen Printing

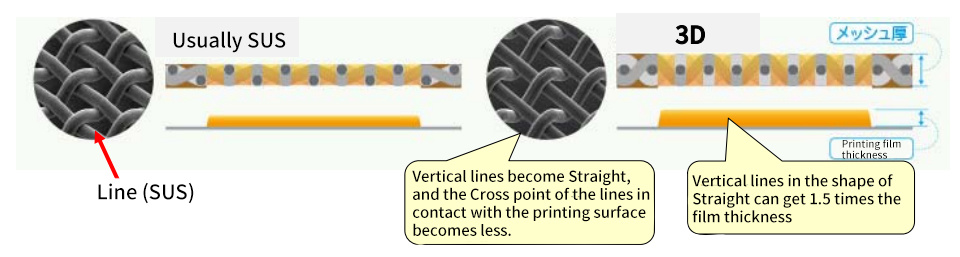

●Screen Mesh

Mesh number: The smaller the number, the thicker the film will be.

General conditions: 3D SUS plate (Asada mesh system) 200 to 250 mesh/inch

3D SUS plate has a special mesh formation method, and even though it has the same number of counts, it has a thicker film than the usual SUS plate.

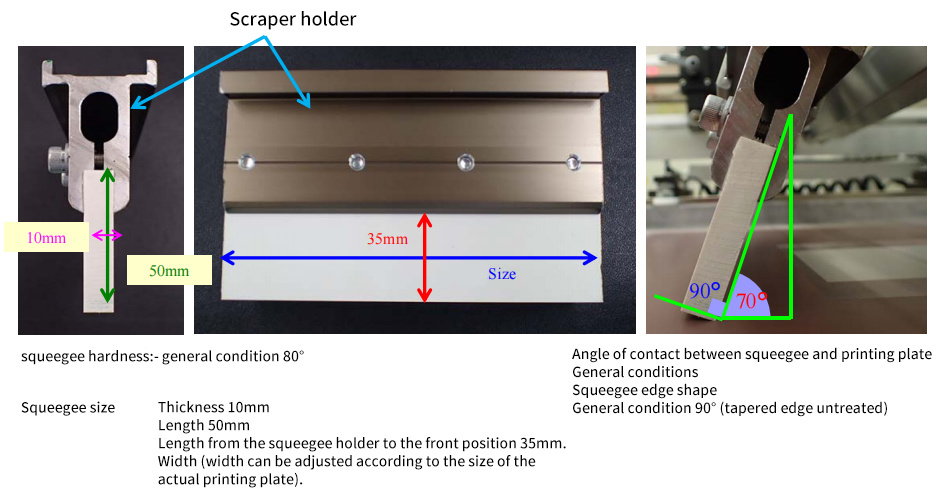

●Screen printing conditions

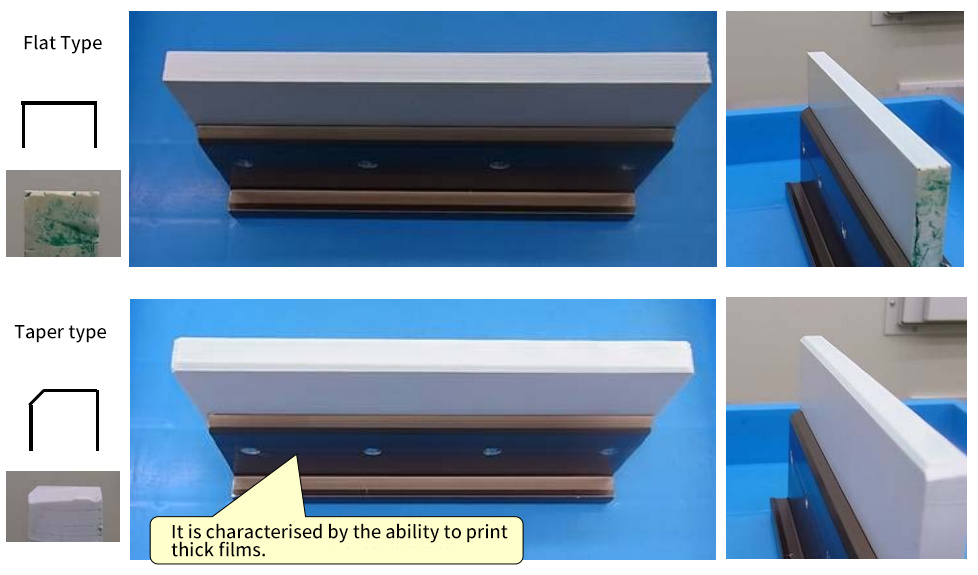

Squeegee hardness: If the hardness is softer, the film thickness will be thicker easily.

General condition: 80°.

Squeegee angle: The smaller the angle, the thicker the film will be.

General conditions: 70°.

Coating speed: The slower the speed, the lower the amount of foam involved.

General conditions: 50-80mm/sec.

Essentials of Screen Printing (Screen Mesh)

●3D screen

Straightening the vertical lines and going to a substantial weave with the horizontal lines ensures about 1.5 times the thickness of the printed film. The lines in contact with the printing surface have fewer crossings, which improves flatness after printing.

●Advantages of 3D screens

①Approximately 1.5 times the thickness of the printed film compared to a screen with the same wire diameter.

②Increased flatness after printing.。

③Reduces the occurrence of pinholes.

Essentials of Screen Printing (Squeegee)

Recommend products

SPS-AS carbon fiber squeegee for duplex drum screen printing machine

SPS-AS carbon fiber squeegee is suitable for reciprocating cylinder screen printing machine. It uses carbon fiber board and Japanese ASM anti-static solvent-resistant polyurethane rubber. The printing quality is stable and the service life is high.

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

In the process of screen printing, squeegee, screen plate, substrate material and other mutual friction, generating static electricity. When static electricity accumulates to a higher voltage difference, the edge of the pattern will produce flying ink, drawing and other bad.SPS-ASM anti-static squeegee resistance <108Ω, part of the charge through the squeegee dissipation, reduce the voltage difference, to avoid flying ink and wire drawing and other problems.

In the process of cell production, the effect of screen printing will directly affect the conversion efficiency of the cell, the core of printing is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must remain innovative, when writing higher screen printing requirements in just ten years, the requirements of the gate line is becoming more and more fine, has been from the initial 60um into the current 30um, or even finer; Subsequent to the replacement of the squeegee (as shown in the figure below), and now SPS-AS-SL single-sided photovoltaic carbon fibre squeegee is becoming more and more popular!

FGB-MP Glass Fibre Board Squeegee

SPS-MP-X series squeegee is a new generation of one-piece squeegee specially developed by Plet and Japan Polyurethane Chemical Company for the narrow line width printing of battery cells. Compared with the traditional sanding squeegee, it has significant effect on wet weight control, printing life and efficiency improvement, etc. Using this squeegee can achieve the purpose of cost reduction and efficiency improvement.

1. Manufactured using Japanese squeegee processing, it exhibits superior solvent and wear resistance; 2. The fiberglass board scraping glue combines the fiberglass board with scraping glue, offering the elasticity of the scraping glue and the structural support of the fiberglass board. This allows for a stable printing angle to be maintained even during extended periods, ensuring uniform ink thickness.