TC diffusion Ink

- Commodity name: TC diffusion Ink

- 汽车内饰-IML: Printing diffusion ink can improve the lighting part of the lamp hole on the product, see the lamp beads of the display motherboard, and solve the problem of uneven distribution of the appearance light source.

Use

Applicable to: Membrane switches, automotive instruments, IMD in-mould injection moulding, home appliance glass, kitchenware glass, electronic display glass decoration and so on.

Product Characteristics

In all home appliance panels, home appliance glass, kitchenware glass, electronic display glass display motherboard will have light parts of the transparent small window, the product and the fuselage fit after assembly, if not printed diffusion ink, when the power supply is powered on when the light is on, the appearance of the product will be seen to display the filament of the motherboard, the appearance of the distribution of light sources is not consistent, and printing diffusion ink on the product can improve this phenomenon, can not see to show the filaments in the motherboard, the appearance from different angles to see the light source is also distributed uniformly. The printing of diffusion ink on the product can improve this phenomenon, the filament in the display motherboard can not be seen, and the light source irradiated from different angles in the appearance is also uniformly distributed.

Printing materials

PET, PC, hardened acrylic, ordinary glass, tempered glass.

Storage conditions

The shelf life of the TC series is 1 year from the time of mixing unopened and 6 months after opening and use. The inks should be stored in dry, cool and ventilated (5-30°) conditions.

Physical Property Test (I)

Model: TC-2500

Curing agent: C-200 Add proportion %10

Substrate: common glass, toughened glass, composite materials

Screen: 200 mesh polyester silk screen, photopolymer film thickness 8μ, tension 15N

Drying: 110℃, 20 minutes

| Pilot project | Test Methods | In the end |

| Adhesion① | BAG test 3M tape peeling 100% no shedding | Eligible (voter etc) |

| Adhesion② | Finger-scratch after a hundred strokes No peeling | Eligible (voter etc) |

| Alcohol-resistant | Pressure 500G for 50 wipes | Bottomless |

| Oil-proof | Hand cream rubbed in 50 times | Anomaly-free |

| Acid resistance | 5 per cent aqueous sulphuric acid solution for 5 hours | Anomaly-free |

Physical Property Test (II)

Model: TC-2000, 2100, 2200

Curing agent: 240 Add proportion %10

Substrate: treated PET, PC, hardened acrylic.

Screen: 200 mesh polyester silk screen, photopolymer film thickness 8μ, tension 15N

Drying: 85℃, 30 minutes

| Pilot project | Test Methods | In the end |

| Adhesion | BAG test 3M tape peeling 100% no shedding | Eligible (voter etc) |

| Alcohol-resistant | Pressure 500G for 50 wipes | Bottomless |

| Heat resistance | ISO 3248: Conditions are 80°C for 400 hours, observing changes in the appearance of the moulded parts and abnormalities. | Anomaly-free |

| Thermal cycling | After 10 test cycles under the condition of "-40℃, 2.5 hours → 2.5 hours at room temperature → 2.5 hours at 90℃ → 2.5 hours at room temperature", observe the changes in the appearance of the moulded parts and the abnormalities. | Anomaly-free |

| Temperature and water resistance | JIS K 5600-6-2: Observation of changes in appearance and abnormalities of moulded parts after immersion in ISO 2812-2, 40°C warm water for 48 hours. | Anomaly-free |

Disclaimer: The above data obtained from laboratory testing, does not represent the end customer quality assurance, although the same parameters may be contrary to the situation, only to ensure that the purchase value and the value of use. Does not assume any user, buyer, distributor and other individuals or enterprises due to direct or indirect, special or accidental reasons for the loss of responsibility and liability, please test to meet the requirements in the batch to continue to use.

Recommend products

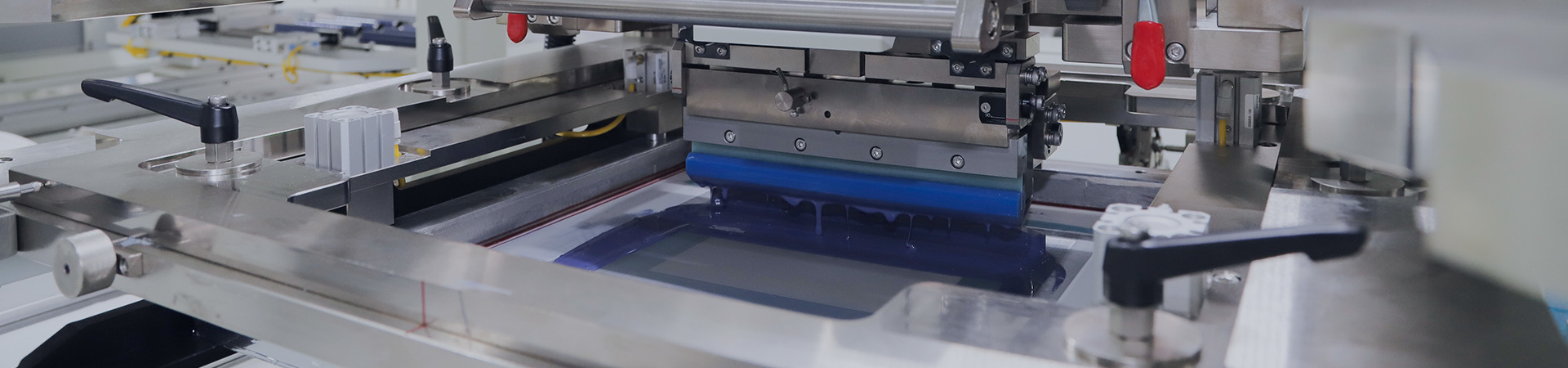

SPS-AS carbon fiber squeegee for duplex drum screen printing machine

SPS-AS carbon fiber squeegee is suitable for reciprocating cylinder screen printing machine. It uses carbon fiber board and Japanese ASM anti-static solvent-resistant polyurethane rubber. The printing quality is stable and the service life is high.

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

In the process of screen printing, squeegee, screen plate, substrate material and other mutual friction, generating static electricity. When static electricity accumulates to a higher voltage difference, the edge of the pattern will produce flying ink, drawing and other bad.SPS-ASM anti-static squeegee resistance <108Ω, part of the charge through the squeegee dissipation, reduce the voltage difference, to avoid flying ink and wire drawing and other problems.

In the process of cell production, the effect of screen printing will directly affect the conversion efficiency of the cell, the core of printing is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must remain innovative, when writing higher screen printing requirements in just ten years, the requirements of the gate line is becoming more and more fine, has been from the initial 60um into the current 30um, or even finer; Subsequent to the replacement of the squeegee (as shown in the figure below), and now SPS-AS-SL single-sided photovoltaic carbon fibre squeegee is becoming more and more popular!

FGB-MP Glass Fibre Board Squeegee

SPS-MP-X series squeegee is a new generation of one-piece squeegee specially developed by Plet and Japan Polyurethane Chemical Company for the narrow line width printing of battery cells. Compared with the traditional sanding squeegee, it has significant effect on wet weight control, printing life and efficiency improvement, etc. Using this squeegee can achieve the purpose of cost reduction and efficiency improvement.

1. Manufactured using Japanese squeegee processing, it exhibits superior solvent and wear resistance; 2. The fiberglass board scraping glue combines the fiberglass board with scraping glue, offering the elasticity of the scraping glue and the structural support of the fiberglass board. This allows for a stable printing angle to be maintained even during extended periods, ensuring uniform ink thickness.