Squeegee hardness tester

- Commodity name: Squeegee hardness tester

Classification:

Keywords: Squeegee | Screen | Ink

The need for squeegee hardness measurement

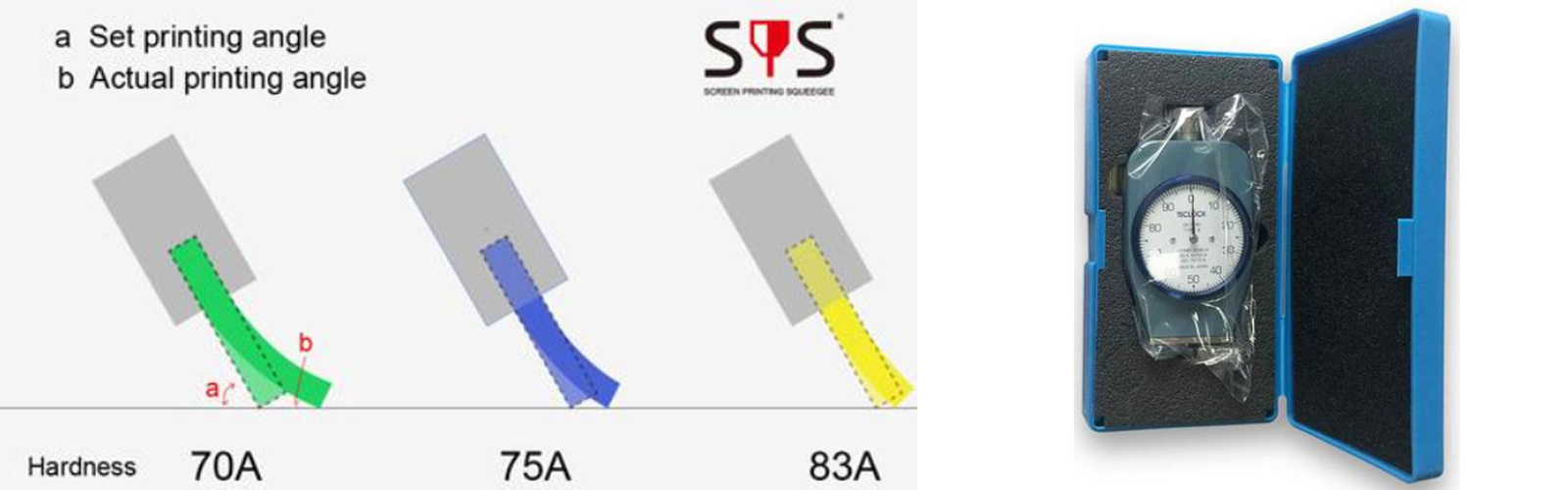

Screen printing requires different squeegee hardnesses to match different printing processes. Different squeegee hardnesses result in different amounts of ink being deposited.

Hardness Tester GS-719N Product Description

The TECLOCK-GS719N Hardness Tester is designed to measure accurately in certain situations such as uneven measuring surfaces or narrow flat surfaces and deep bottoms. GS-719N Hardness Tester meets ASTM D 2240 A/JIS K6253/ISO 7619A standard.

Use

Screen printing squeegee hardness is different, screen printing ink amount is not the same, so in the screen printing process to determine the case, to ensure that each time the use of squeegee hardness uniform.

Japan TECLOCK-GS-719N measuring squeegee hardness accuracy, long service life. Measuring hardness range 0-100 A.

Measuring method

After a long period of time at low temperatures, the hardness of the squeegees cannot be measured immediately when they are moved to room temperature, but should be left at 23° for more than 3 hours to regain its elasticity before the hardness can be tested accurately.

Storage

Store indoors at 40°C or lower, do not store in high temperature and humidity, direct sunlight and ultraviolet rays, do not store near heat generating equipment or dusty places.

The idea of a rubber hardness tester suggests that people's perception of hardness may have unclear meanings, e.g. "slightly soft", values that can be compared in some physical way, or with elastic materials that may be distorted by human hands. When the surface of a specimen is deformed by the pressure generated by a specific shape of indenter by a specific spring load, the specimen generates an elastic force that resists the pressure load.

The "hardness" is the amount of indentation indented by the indenter when the elastic force is equal to the pressure load. Since the so-called specific shape of the indentation and the specific load are values given by human experience or in an experimental sense, the resulting values are "relative physical quantities" without units.

Recommend products

SPS-AS carbon fiber squeegee for duplex drum screen printing machine

SPS-AS carbon fiber squeegee is suitable for reciprocating cylinder screen printing machine. It uses carbon fiber board and Japanese ASM anti-static solvent-resistant polyurethane rubber. The printing quality is stable and the service life is high.

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

In the process of screen printing, squeegee, screen plate, substrate material and other mutual friction, generating static electricity. When static electricity accumulates to a higher voltage difference, the edge of the pattern will produce flying ink, drawing and other bad.SPS-ASM anti-static squeegee resistance <108Ω, part of the charge through the squeegee dissipation, reduce the voltage difference, to avoid flying ink and wire drawing and other problems.

In the process of cell production, the effect of screen printing will directly affect the conversion efficiency of the cell, the core of printing is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must remain innovative, when writing higher screen printing requirements in just ten years, the requirements of the gate line is becoming more and more fine, has been from the initial 60um into the current 30um, or even finer; Subsequent to the replacement of the squeegee (as shown in the figure below), and now SPS-AS-SL single-sided photovoltaic carbon fibre squeegee is becoming more and more popular!

FGB-MP Glass Fibre Board Squeegee

SPS-MP-X series squeegee is a new generation of one-piece squeegee specially developed by Plet and Japan Polyurethane Chemical Company for the narrow line width printing of battery cells. Compared with the traditional sanding squeegee, it has significant effect on wet weight control, printing life and efficiency improvement, etc. Using this squeegee can achieve the purpose of cost reduction and efficiency improvement.

1. Manufactured using Japanese squeegee processing, it exhibits superior solvent and wear resistance; 2. The fiberglass board scraping glue combines the fiberglass board with scraping glue, offering the elasticity of the scraping glue and the structural support of the fiberglass board. This allows for a stable printing angle to be maintained even during extended periods, ensuring uniform ink thickness.