UD Composite squeegee

- Commodity name: UD Composite squeegee

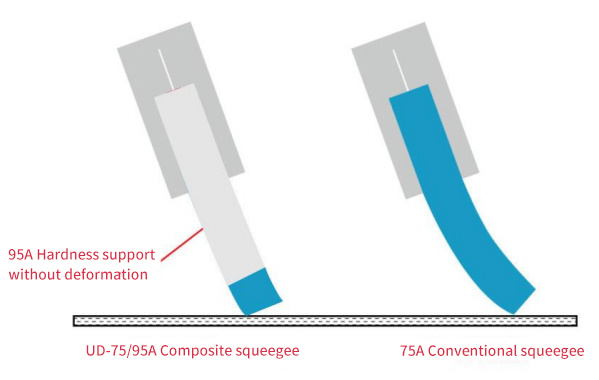

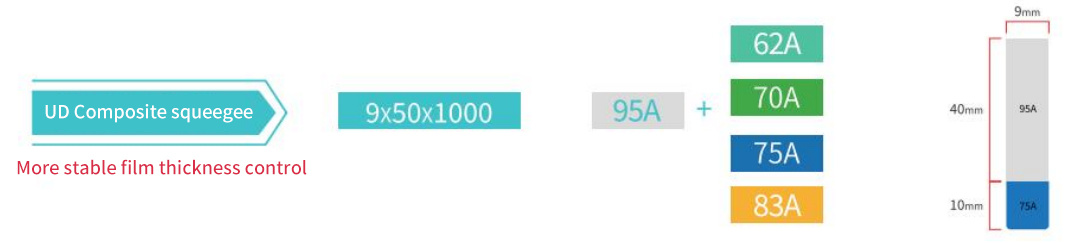

- 精密陶瓷行业概要: 1.Squeegee glue is casting one-piece moulding process casting solvent resistance abrasion resistance excellent;</br> 2.Double-layer different hardness support better, film thickness for a long time printing more uniform;.</br> 3.White part is 95 A, blue part is 65 A/70 A/75 A/83 A.

- 柔性线路-FSR: 1. The squeegee is an integrated casting process, providing superior solvent and wear resistance;</br> 2. The double-layer design with varying hardness offers enhanced support, ensuring more consistent film thickness for prolonged printing;</br> 3. The white section has a hardness of 95 degrees, while the blue section features hardnesses of 65 degrees, 70 degrees, 75 degrees, and 83 degrees.

- 汽车内饰-IME: 1.Squeegee glue is casting one-piece moulding process casting solvent resistance abrasion resistance excellent;</br> 2.Double-layer different hardness support better, film thickness for a long time printing more uniform;</br> 3.White part is 95 A, blue part is 65 A/70 A/75 A/83 A.

Classification:

Keywords: Squeegee | Screen | Ink

Solvent-resistant dual-hardness composite squeegee

SPS-UD With the development of electronic industry, precision screen printing has also been developed rapidly, and the requirements for screen printing squeegees are getting higher and higher. Changzhou PLET has developed SPS-UD double hardness composite screen printing squeegee together with Japanese company, which inherits the good quality of Japanese squeegee, excellent solvent resistance and abrasion resistance, stable screen printing quality and high printing life, suitable for electronic screen printing.

Size and Hardness

Size

| Size(a*b*c) |  |

a(9.2±0.3mm) b(±0.5mm) c(+5mm) | Inspection Methods |

| 9*30*1000mm | Vernier caliper/film scale | ||

| 9*50*1000mm |

Hardness

Hardness measurement: temperature: 23℃; hardness tester: TYPE-GS-719N

Material

Polyurethane

Physical property

| Item | Unit | Polyurethane | |||

| Colour | Cyan 62A | Green 70A | Blue 75A | Yellow 83A | |

| Hardness | JIS-A | 62±3 | 70±3 | 75±3 | 83±3 |

| 100% tensile | MPa | 2.52 | 2.77 | 3.70 | 5.89 |

| 200% tensile | MPa | 3.72 | 4.09 | 5.38 | 8.63 |

| 300% tensile | MPa | 6.50 | 5.85 | 7.38 | 11.1 |

| Maximum Stretch | MPa | 35.1 | 24.6 | 17.2 | 11.7 |

| Tensile limit | % | 632 | 563 | 521 | 523 |

| Rupture strength | KN/m | 45.4 | 55.5 | 67.7 | 81.5 |

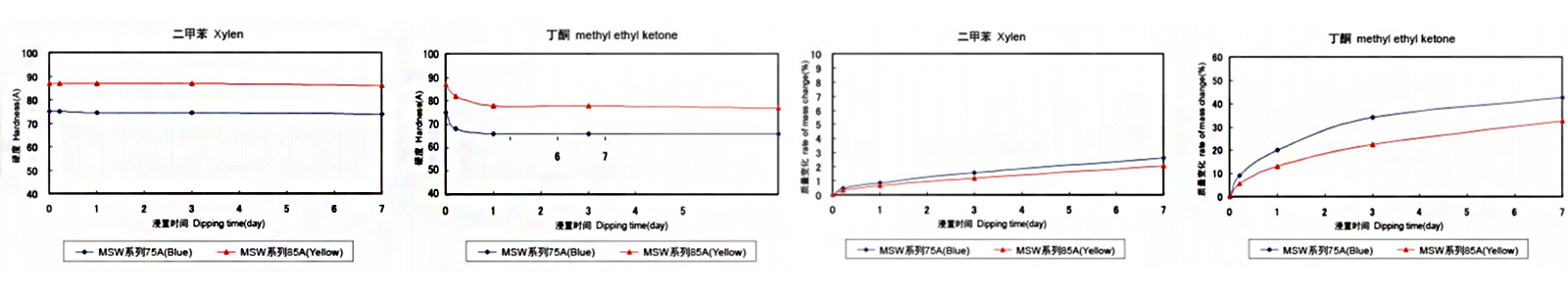

Chemical solvent resistance

Testing time: 7 days

Test solvent: xylene,methyl ethyl ketone

Test items: Hardness change, mass change

Packaging, Storage

Packaging

Paper packing:10Pcs/Box。

Storage

①Indoor storage at 40°C or lower, do not store in high temperature and humidity, direct sunlight and UV radiation. (Recommended storage conditions: 23°C±2°C, 60% or lower humidity)

②Do not store near heat generating equipment or dusty places.

③Prohibit bending and heavy pressure, stack flat and stack no more than 20PCS.

④The squeegee adhesive can not be used immediately after being placed for a long time at low temperature and moved to room temperature, it should be placed at 23° for more than 3 hours before use.

Grinding

①After use, please clean squeegee the ink on the surface and put it on the SPS-DR squeegee holder to rest for 12 hours to wait for solvent release.

②The M model conventional squeegee needs to be clamped in the squeegee holder for grinding; the FGB/AS squeegee with support plate can be removed for grinding.

③ Manual grinder for grinding.

Maximum grinding by 250mesh grinding wheel in one pass Rough grinding 0.5mm/Fine grinding 0.2mm

400mesh grinding wheel maximum single grinding Rough grinding 0.2mm/Fine grinding 0.1mm

④ The squeegee after grinding can be used in conjunction with SPS Sander polisher to polish the edge of the blade, making the blade smoother.

Attention

All SPS squeegees can be ground several times, grinding without melting, fine grinding surface and smooth kerf.

SPS-SG squeegee grinder can provide various customised grinding wheels: U-type, C-angle, R-angle (K1-K5).

Recommend products

SPS-AS carbon fiber squeegee for duplex drum screen printing machine

SPS-AS carbon fiber squeegee is suitable for reciprocating cylinder screen printing machine. It uses carbon fiber board and Japanese ASM anti-static solvent-resistant polyurethane rubber. The printing quality is stable and the service life is high.

GM-IO is a UV curable screen printing insulating ink with excellent adhesion, high flexibility, good printability and UV curing fast drying characteristics, suitable for blood glucose meters, keyboard circuits, membrane switches and so on.

In the process of screen printing, squeegee, screen plate, substrate material and other mutual friction, generating static electricity. When static electricity accumulates to a higher voltage difference, the edge of the pattern will produce flying ink, drawing and other bad.SPS-ASM anti-static squeegee resistance <108Ω, part of the charge through the squeegee dissipation, reduce the voltage difference, to avoid flying ink and wire drawing and other problems.

In the process of cell production, the effect of screen printing will directly affect the conversion efficiency of the cell, the core of printing is the aspect ratio of the silver paste after printing. Therefore, the screen, silver paste and squeegee must remain innovative, when writing higher screen printing requirements in just ten years, the requirements of the gate line is becoming more and more fine, has been from the initial 60um into the current 30um, or even finer; Subsequent to the replacement of the squeegee (as shown in the figure below), and now SPS-AS-SL single-sided photovoltaic carbon fibre squeegee is becoming more and more popular!

FGB-MP Glass Fibre Board Squeegee

SPS-MP-X series squeegee is a new generation of one-piece squeegee specially developed by Plet and Japan Polyurethane Chemical Company for the narrow line width printing of battery cells. Compared with the traditional sanding squeegee, it has significant effect on wet weight control, printing life and efficiency improvement, etc. Using this squeegee can achieve the purpose of cost reduction and efficiency improvement.

1. Manufactured using Japanese squeegee processing, it exhibits superior solvent and wear resistance; 2. The fiberglass board scraping glue combines the fiberglass board with scraping glue, offering the elasticity of the scraping glue and the structural support of the fiberglass board. This allows for a stable printing angle to be maintained even during extended periods, ensuring uniform ink thickness.