这里是标题一h1占位文字

Requirements for the selection and use of SPS customised squeegee

Release time:

2024-05-03

Squeegee need to be cleaned immediately after use, the knife mouth facing up, rest 12 hours before printing or grinding.

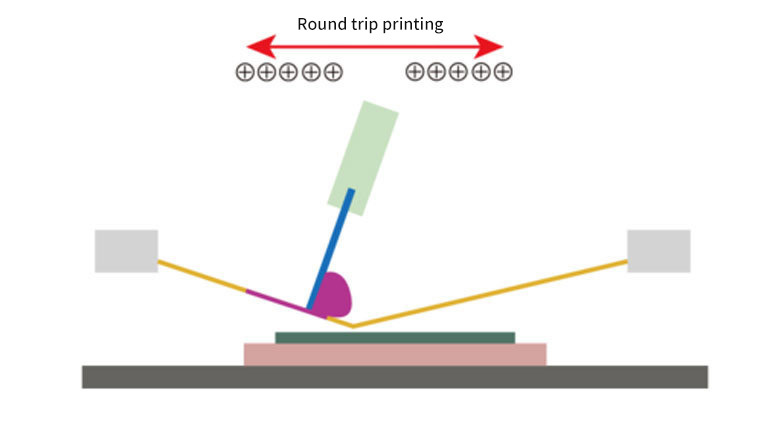

In screen printing, squeegees are used to transfer ink through the mesh holes that are not blocked by the emulsion. When the squeegee is pressed against the screen, it receives the opposite force of the screen tension and leaves the screen, at which point the ink is transferred and printed onto the substrate.

The pressure of the squeegee is transmitted to the edge of the squeegee by a minimum force to transfer the ink. Reaching this pressure causes the squeegee to bend, and a hard squeegee can overcome this bending problem, but this will accelerate the wear of the screen. Therefore, in the printing process, you need to choose the appropriate hardness according to the requirements of the printing content.

SPS squeegee storage requirements.

Squeegees should be placed as flat as possible, avoid bending, stacked flat not more than 20pcs, and placed in a cool and lightproof environment.

The squeegee should be stored in low temperature, and should be placed in 25C environment for more than 3 hours before use if it can't be used immediately after transporting to the workshop.

Storage environment 0℃<temperature<40℃,humidity<60°and keep away from light.

The use of squeegee in the short stop, with the placement of the knife mouth is strictly prohibited downward, squeegee try not to contact other objects to avoid deformation.

Squeegee need to be cleaned immediately after use, the knife mouth facing up, rest 12 hours before printing or grinding.

You can also learn more dynamic